Upcoming Events

Textile industry in India is heading towards a radical change aiming at remarkable progress and development. In order to cater to the utmost needs of this industry, a great responsibility lies on the Technical Institutions, which imparts Textile education in shaping the technocrats to give their best. In this direction, the Department of Textile Technology of Bapuji Institute of Engineering and Technology, Davangere (Karnataka), is gradually marching towards pursuit of technical excellence in textile education. Be it the pursuit of the best textile education in the country, or a friendly and lively campus environment to provide a broad, close knit social fabric of national integration – Department of Textile technology offers the best of the both to the students. The philosophy of the department is “Work is worship”. The textile students in their tasks aim at achieving excellence, efficiency and effectiveness. The seed of such a work culture is sown and the seedlings are carefully nurtured in the students graduating from this renowned department.

Vision

To be the center of excellence in textile education, besides serving the society by undertaking various innovative research, industry and society related activities.

Mission

- To impart the basic science, engineering, textile, garment and fashion education for the growth and development of the students by providing effective teaching and learning processes.

- To impart practical/research knowledge through industrial training and projects.

- To empower the students with positive approach and presentation skills by conducting workshops and conferences.

- To inculcate ethical values of various virtues, which enable them to become successful textile technologists and good citizens of the nation.

Program Educational Objectives (PEOs)

- Graduates of the program will have successful career in manufacturing, quality assurance, product development and technical sales segments of textile industry.

- Graduates can inculcate research capabilities in various textile technology fields to innovate new products and adopt themselves in the world of constantly evolving technology.

- Graduates will apply acquired knowledge in solving technological challenges of the textile industry.

- Graduates will exhibit entrepreneurship, leadership quality, team work and incorporate societal needs to practice their profession with high level of legal and ethical responsibilities.

Program Specific Outcomes (PSOs)

- The students will be capable of designing and developing various textile products and control and improve the various manufacturing processes and quality of textile products.

- The students will be able to communicate their ideas, findings, and knowledge through project work, technical publications and technical conferences.

SWOT

a) Strength

- Supportive and committed management.

- Qualified and experienced faculty members

- Good infrastructure facilities.

- Well-equipped R&D center where not only our research scholars but outside researchers also come to carry out their work.

- Many new products have been developed in the dept. which are well accepted by the industry

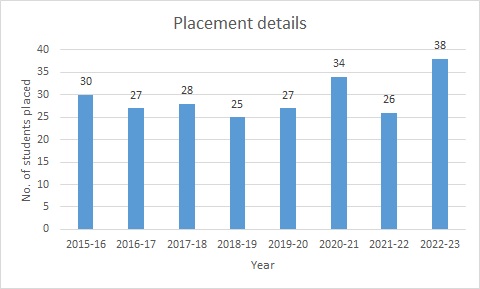

- All most 100% placement in each year.

- Department gets maximum number of University ranks.

- Regular industrial visits/ Internships

- Well placed Alumni and their network.

b) Weakness

- Lesser Number of modern equipment in laboratory.

- Less Number of Technical & supporting staff.

- Lesser number of publications in indexed journals.

- Lesser number of research grants and funded research projects

- Inadequate number of research scholars

- Less collaborative research with premier organizations.

- Lack of initiative in the process of publishing and acquiring patents.

c) Opportunities

- Only Textile department in Karnataka with qualified staff and well equipped laboratories which can attract students.

- Textile Park which has been developed near the college (3 km) can provide good opportunity to students.

- As the department is getting maximum University ranks it is easy to attract the multinational companies to conduct campus interview

- Enhancing Industry–Institute interaction through MOUs.

- Enhancing research activities through government funding agencies

- Establishing skill development centre / centre of excellence / start-ups / incubation centre.

- Organizing programs to faculty and supporting staff to cope up with changing in education policies and hands on training to students

d) Threats

- Competition from autonomous and deemed-to-be universities

- Coping up with fluctuating trends of industry.

- Drastic changes in curriculum and teaching-learning process/ Training of students as per the changing curriculum

- Fluctuating trend in global economy.

- Decreased admission trend due to wide availability of other programs.

- Fast obsolescence of existing technologies and emergence of new technologies.

- Lack of interest among students to pursue higher studies / research.

- Attracting meritorious students to the department

e) Future plans of the department:

- To make the department as one of the best Textile departments in the country

- To take up many national and institutional level research projects.

- To conduct International Seminars and conference.

- To equip the laboratories with most modern facilities.

- To create the best conducive atmosphere for the students learning in the department.

Dr.Dinesh Y.N

Professor & HOD

Dr. Y.N.Dinesh did his Bachelor of Technology in Textile Technology in GSKSJTI-Bangalore in 1990 securing second rank. He obtained his Master’s Degree in 1993 from IIT Delhi, and Ph. D. from VTU, Belagavi in 2019. He worked as lecturer in Rural Engineering College Hulkoti from Feb-1993 to May 1995. He joined BIET Davangere as lecturer in June 1995, worked as lecturer from June 1995 to May 2005, as senior lecturer from June 2005 to July 2007, as Assistant Professor from August 2007 to November 2021 and presently working as Professor and Head of the department. He has published several papers in National and International Journals. He has actively involved in various funded research projects and worked as project assistant and Project coordinator for various sponsored projects.

Faculty Members

Technical Staff

Deepashree S Horapeti

Instructor

C.Basavarajaiah

Fitter

Supporting Staff

Publications

| Sl.no | Faculty Name | Google Scholar link | IRINS |

|---|

Books/Book Chapters Published

| Sl. No | Title of the Book Chapter | Author/s | Year of Publication | Name of Publisher/s |

|---|---|---|---|---|

| 5 | Silk Fibres, in Handbook of natural fibres: Types, properties and factors affecting breeding and cultivation (Volume-I), | Chapter contribution by Dr. K Murugesh Babu and Ed. by, Prof.Ryszard Kozlowski,Chapter contribution by Dr. K Murugesh Babu and | 2012 | Woodhead Publishing Ltd, UK |

| 3 | The Use of Smart Materials in Cold Weather Apparel, in Textiles for Cold Weather Apparel, p 84-109, | Chapter contribution by Dr. K Murugesh Babu and Ed. by Dr John T Williams, | 2009 | Woodhead Publishing Ltd, UK |

| 2 | Testing Intelligent Textiles in Fabric Testing, p 275-308, | Chapter contribution by Dr. K Murugesh Babu and Ed. by, Prof. Jinlian Hu, | 2008 | Woodhead Publishing Ltd, UK |

| 1 | Key Issues in Testing of Damaged Textiles in Fabric Testing, p 309-338, | Chapter contribution by Dr. K Murugesh Babu and Ed. by, Prof. Jinlian Hu, | 2008 | Woodhead Publishing Ltd, UK |

| 6 | I Edition - A text book on Silk – Processing, Properties and Applications | Dr. K. Murugesh Babu | 2013 | Woodhead Publishing Ltd, Cambridge, UK |

| 9 | II Edition - A text book on Silk – Processing, Properties and Applications | Dr. K. Murugesh Babu | 2018 | Elsevier, USA |

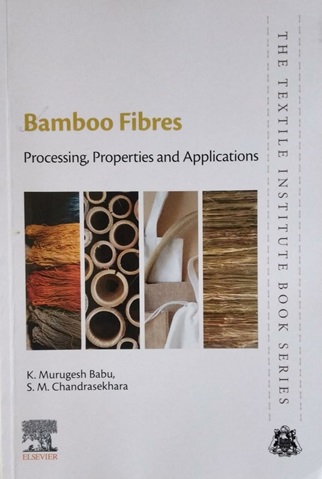

| 12 | Bamboo Fibers-Processing, Properties and Applications | K Murugesh Babu and S M Chandrasekhara | 2023 | Elsevier |

| 9 | Chapter 3 - Animal Fibres – Silk, Handbook of Fibrous Materials, | Chapter contribution by Dr. K Murugesh Babu and Ed. by Jinlian Hu, Bipin Kumar and Jing Lu, | 2020 | Wiley-VCH Verlag GMBH & Co. KGaA, |

| 10 | Silk Fibres – Structure, Properties and applications, Chapter-11 p 385-415 in Hand Book of Natural Fibres, (Second edition) , : Types, Properties and Factors affecting Breeding and Cultivation (Volume-I),, | Chapter contribution by Dr. K Murugesh Babu and Ed. by, Ryszard Kozlowski and Maria Mackiewicz-Talarczyk, Elsevier Ltd.Chapter contribution by Dr. K Murugesh Babu and | 2020 | (Woodhead Publishing Ltd, UK), |

| 11 | Silk-Production and Future Trends, Chapter-3 p 121-144 in Hand Book of Natural Fibres, (Second edition) : Processing and Applications, Volume-II,, | Chapter contribution by Dr. K Murugesh Babu and Ed. by, Ryszard Kozlowski and Maria Mackiewicz-Talarczyk, | 2020 | Elsevier Ltd. (Woodhead Publishing Ltd, UK), |

| 8 | Silk from Silkworms and Spiders as High-performance Fibers, in Structure and properties of high-performance fibers, Chapter-13, p 325-363, | Chapter contribution by Dr. K Murugesh Babu and Ed. by, Prof.Gajanan Bhat,Chapter contribution by Dr. K Murugesh Babu and | 2016 | Elsevier Limited, Oxford, United Kingdom, |

| 7 | Natural Textile Fibres: Animal and Silk Fibres, in Textiles and Fashion: Materials, Design and Technology, Chapter-3, 57-78 | Chapter contribution by Dr. K Murugesh Babu and Ed. by, Prof. Rose Sinclair, | 2014 | Woodhead Publishing Ltd, UK |

| 4 | Silk Production and Future of Natural Silk Manufacture,(Chapter-1) in Hand Book of Natural Fibres, Processing and Applications, Volume-II,, | Chapter contribution by Dr. K Murugesh Babu and Ed. by, Prof.Ryszard Kozlowski, | 2012 | Woodhead Publishing Ltd, UK |

Grants

- Market Survey on the Potential of Silk Yarn Degumming and Dyeing Machine Evaluation System Silk Hank Dyeing Machine, Funding agency: Swiss Development Cooperation, Bangalore, 1997, 1.18 Lakhs -completed

- Design and Development and Field Testing of Silk Yarn Degumming and Dyeing Machine - Phase-I, Funding agency: Swiss Development Cooperation, Bangalore, 1999-2000, 17.15 Lakhs- Completed

- Design and Development and Field Testing of Silk Yarn Degumming and Dyeing Machine - Phase-II, Funding agency: Swiss Development Cooperation, Bangalore, 2000-2002, 25.99 Lakhs- Completed

- Dissemination of Technology of Silk Yarn Degumming and Dyeing Machine-Phase-III, Funding agency: Swiss Development Cooperation, Bangalore, 2003-2004, 7.0 Lakhs- Completed

- Development of Silk Reeling machine and Pre-loom Accessories, Funding agency: DST, New Delhi, 1994-97, 8.76 Lakhs- Completed

- Pre-Loom Accessories, Funding agency: KSCST, Bangalore, 1996, 0.46 Lakh- Completed

- Market Survey of potentials of silk yarn degumming and dyeing machine evaluation system, Funding agency: Swiss Development Cooperation, Bangalore, 1997, 1.18 Lakh- Completed

- Fabrofeel-A computerized Instrument to measure hand of fabric, Funding agency: AICTE, New Delhi, 2004-05, 7.0 Lakh- Completed

- Eco-friendly Crease Resistant Finishes for Silk, Funding agency: AICTE, New Delhi, 2003-05, 4.6 Lakhs- Completed

- Development of Bio-composites from Natural Fibres, Funding agency: (Under RPS Scheme, Funding agency: All India Council for Science and Technology, New Delhi, 2009-11, 8.0 Lakhs- Completed

- Skill development training Textile/Garment Technology (Under New Textile Policy 2013-2018 Scheme, Funding agency: Dept. of Handloom and Textiles, Govt. of Karnataka, Bangalore, India, 2013-2018, 10.00 Lakhs-Completed

- Textile Skill Upgradation Centre Textile/Garment Technology, (Under New Textile Policy 2013-2018 Scheme), Funding agency: Dept. of Handloom and Textiles, Govt. of Karnataka, Bangalore, India, 2013-2018, 50 Lakhs- Completed

- New Age Innovation Network (NAIN), a program by the Govt. of Karnataka, sectioned Rs. 3 Lakh for the student project titled "Modification of hand operated Khadi yarn spinning machine for improved yarn quality and production". Dr S M Chandrasakara, Associate Professor, is the mentor of the project.

- New Age Innovation Network (NAIN), a program by the Govt. of Karnataka, sectioned Rs. 3 Lakh for the student project titled "Development of Bio-composites from areca husk fibres for sound and thermal insulation application" guided by Nandeesh R S.

Patents

- No Patent as on today

Laboratory Facilities

| S.No. | Name of Lab | Qty | Configuration/Specification | Software |

|---|---|---|---|---|

| 1. | CAD/CAM | 12 | Desk top computers - 12 (HP, HCL,) | Wonder weaves textile design software -4,94,000=00 Tuka cad interactive software (01 Industrial and 05 light version including demo versions)- 93,440/- Wonder weaves textile design software Up gradation of software (4 systems)- 1,56,000=00 |

| 1. | Minolta Spectrophotometer | 1 | -- | -- |

Major Equipments

- Blow-Room L.R.Make Cotton Processing Line Model B02/1 , Mixing Bale Opener, ERM Cleaner, Hopper Feeder, Mono Cylinder Cleaner, Two Bladed Beater, Krischner Beater, Scutcher

- Carding L.R. Make Crystallina

- Draw Frame L.R. Make Model D02/S

- Speed Frame L.R.Make Lf-1400

- Ring Frame L.R.Make Dj/5

- King Tex – Rapier Weaving Loom Model –Kt 566111

- Open Bath Beaker Dyeing Machine

- Fabric Dyeing Machine

- Water Bath (6 Holes)

- Dye Master (Open Bath)

- Hounsfield Tensile Testing M/C

- Digital Humidity Tester

- Light Fastness Tester

- High Volume Instrument

- JUKI Industrial sewing machines - 11 Nos

- Universal Tensile Testing Machine

Classroom

Class Room 305 1. Well ventilated Class rooms are kept clean and tidy 2. Each class room is provided with a. Sufficient no. of desks, b. Podium, c. Black board d. Projector screen e. OHP f. LED Projector

Class Room 306 1. Well ventilated Class rooms are kept clean and tidy 2. Each class room is provided with a. Sufficient no. of desks, b. Podium, c. Black board d. Projector screen e. OHP f. LED Projector

Class Room 307 1. Well ventilated Class rooms are kept clean and tidy 2. Each class room is provided with a. Sufficient no. of desks, b. Podium, c. Black board d. Projector screen e. OHP f. LED Projector

Department Library

Under the Textile forum a small library is maintained which is taken care by student convener and faculty convener. Departmental library consists of various study materials, monograms, project reports of final year students, text books donated by students.

Department Advisory Board (DAB) Members

| S.No. | Member | Designation |

|---|---|---|

| 1 | Dr. H B Aravind, | Professor, Principal |

| 3 | Prof. Y Vrushabhendrappa, | Director |

| 3 | Dr. Y N Dinesh | Professor & Head Dept. of Textile Tech, BIET |

| 4 | Dr. S M Chandrasekhara | Associate Professor, Dept. of Textile Tech, BIET |

| 5 | Dr. Y N Dinesh, | Associate Professor, Textile Tech, Deputy Dean |

| 5 | Dr. Nirmala C R | Prof and Head, CSE |

| 6 | Dr. K B Ravindra | Associate professor, Textile Tech, BIET |

| 8 | Hanumantha Naik | Asso professor & HOD, Textile Tech, GSKSJTI, Bangalore |

| 9 | Mr. Aditya Chigateri | Alumni member |

| 9 | Dr. Hanumantha Naik | HOD, Dept. of Textile Technology, GSKSJT Institute, Bangalore |

| 10 | Mr. Nagaraja | Alumni Parent |

| 11 | Amulya S | Student V sem |

| 12 | Mr. Manjunatha | President, Anjaneya Cotton Mills, Davangere, Industrialist |

Program Assessment Committee (PAC) Members

| S.No. | Member | Designation |

|---|---|---|

| 1 | Dr. Y N Dinesh | Professor and Head, Dept. of Textile Tech |

| 2 | Dr. S M Chandrasekhara | Associate Professor, Dept. of Textile Tech |

| 3 | Dr. K B Ravindra | Associate Professor, Dept. of Textile Tech |

| 4 | Mr. Nandikol | Asst. Professor, Dept. of Textile Tech |

| 5 | Mr. Nandish | Asst. Prof., Dept. of Textile Tech |

Students placed in various companies

Mr.P. ASHOK KUMAR

Technical DirectorThuraiyur Main Road, Ponneri (Po), Namakkal – 637 013. Cell No.9443333770

He was born on 14th June 1979 in Attur, Tamil Nadu, He did his Schooling from Monfort, Yercaud. He did his Bachelor of Technology in Textile Technology at Bapuji Institution of Engineering and Technology Davangere, Karnataka State. In 2001, he began his Career under “PSK Group” and became the Technical Director of Saranya Spinning Mills (P) Ltd., in Ponneri, Namakkal. In the meantime, he has completed his Master of Business Administration from Alagappa University. Under his leadership, Saranya Spinning Mills got various awards in the 5’S’ implementation and remarkable expansion in Ring Spinning, Open End Spinning, Airjet Spinning, Sizing, Weaving and Bed Linen during the years 2001 to 2019. In 2019, he became the Managing Director of Saranya Spinning Mills (P) Ltd., He is also a Member of “Kongunadu Educational Charitable Trust” – with Kongunadu College of Engineering and Technology; Kongunadu Polytechnic College and Kongunadu College of Education, Thottiam, under its banner. He is also holding the position of Joint Secretary of these Institutions.

Shagufta Parveen

Manager – Marketing Shahi Exports Pvt. Ltd, Bangalore shagufta.parveen45@gmail.com +91 9739985386 +91 9886771203

She obtained her Bachelor of Technology in Textile Engineering from Bapuji Institute of Engineering and Technology, Davangere affiliated to Visveswaraya Technological University, Belgaum, Karnataka in the Year – 2007. Presently working as Manager – Marketing, in Shahi Exports Private Limited, Bangalore, Karnataka from July - 2007 to Till Date. With over 12 years of total experience in the field of garment production and merchandising with a leading garments manufacturer, managing various product categories (including Outer Wear) for International Buyers (Clients). She is Proficient in handling activities right from order inquiry stage to shipment execution and sailing through all the process. Conversant with Buyer, production team, suppliers and internal support teams to bring out the seamless execution. She also gained significant exposure of working on various products which include products like Shirts, Bottoms and outerwear like fleece, soft shell, Insulated jackets, seam sealed jackets and double jackets. An effective communicator with good presentation, interpersonal and leaderships kills. She has additional qualities such as managing product safety compliance, ensuring the Testing requirements are as per the Buyer Norms, managing price & delivery terms with suppliers, identification and allocation of subcontracting for Printing, Quilting, and Fringing processes. She is responsible for training team members on Technical aspects, ERP (CRM, Infor M3) and also responsible for induction of new joinees into Marketing department.

Staff Achievements

- K B Ravindra, Associate Professor, Y N Dinesh, Asst Professor and S M Chandrasekhara Asst. Professor, are awarded Ph. D. degree from VTU, Belagavi in March 2019. Dr. K. Murugesh Babu was the research guide for them.

- Dr. K. Murugesh Babu was awarded as Best Guide from Karnataka State Council for Science and Technology, Bangalore, India in 2017 for guiding students’ project(Project Title: Design & Development of Natural Fibre Extracting Machine)

- Dr. K. Murugesh Babu was Recognized as ‘Technical Referee’ for the following International Journals: Textile Research Journal (USA), Journal of Applied Polymer Science (USA), Research Journal of Textiles and Apparel (Hong Kong), (Acted as a Special Editor for May 2008 issue of this journal), Smart Materials and Structures (USA), Journal of Industrial Ecology, Journal of Industrial Textiles, Journal of Natural Fibres.

- Dr. K. Murugesh Babu was recognised as ‘Expert Reviewer’ for “Biotechnology Ignition Grant (BIG) KIIT- Technology Business Incubator– Bhubaneswar, India in 2016

- Dr. K. Murugesh Babu was selected as Subject Expert/Advisor’ Union Public Service Commission, New Delhi

- Dr. K. Murugesh Babu was nominated as “Member of Scientific Partners” for the Master’s Programme in Textiles of University of Douala, Douala, Cameroon and Central Africa.

- Biography of Dr. Murugesh Babu published in Marquis Who's Who 2010, 27th Edition

- Dr. K. Murugesh Babu authored a text book titled Silk- Processing, properties and applications and published in Elsevier (USA) in 2016 and second edition of the same book was released in 2019

- Mr. Nandeesh R S attended 2 days training program on “Quality Certification of products” organized by Bureau of Indian Standards (mentors club) in Margao, Goa, on 13th and 14th Feb 2024

- Dr. K B Ravindra, Dr. Dinesh Y N and Dr. S M Chandrasekhara, published a paper in Asian Dyer, June-July 2022, titled “Antimicrobial activity of fabrics with natural dyes”.

- S N Ramesh, Associate Professor was awarded Ph. D. degree from VTU, Belagavi in March 2019. Dr. J S Muralidhara, was his research guide.

- Mrs. Kavya L, hss reported for the duty as Assistant Professor, in Department of Textile Technology on 9-9-24.

- Mr. Nandeesh attended one day seminar on “Research project proposal submissions” at Biotech seminar hall on 21-10-24.

- Under Dr. S M Chadrasekhra, Associate Professor, four research scholores have registered for Ph.D in Textile Technology at DEpt. of Textile Technology research centre, BIET, under VTU Belagavi.

- Dr. Y. N. Dinesh appointed as External member for evaluation of Ph. D scholars of research center in Textile board, Shivaji university, Maharastra

- Dr. Dinesh Y N, Professor and Head, appointed as chairman and Dr. Chadrasekhara, Associate Professor as member of BOS of VTU, Textile/Silk Board for the year 2022-2023.

- Dr. Y. N. Dinesh, and Dr. Chandrasekhara S M are recognized as research supervisors, Department of Textile Technology and research Centre, BIET by VTU, Belgaum and four research scholars have registered for Ph. D under them.

- Under Dr. Y N Dinesh, Professor and Head, four research scholores have registered for Ph.D in Textile Technology at DEpt. of Textile Technology research centre, BIET, under VTU Belagavi.

- Dr. Y N Dinesh successfully completed the NPTEL Online certification course on “Effective Engineering Teaching in Practice” with a consolidated score of 92% in Jan-Feb 2024

- Mr. Shashank attended training program on “VTU Consortium e-resources for library professionals for faculty and research scholars” held at UBDT, Davangere on 23-10-24

- Dr. Dinesh Y N, Dr. S M Chandrasekhara and Dr. K B Ravindra faculty members attended two day workshop on “Effetcive English Communication, Content and Language Integrated Learning (CLIL) on 12-13 Sept. 2024 held at Placement cell, BIET.

- K B Ravindra, Associate Professor, Y N Dinesh, Asst Professor and S M Chandrasekhara Asst. Professor, are awarded Ph. D. degree from VTU, Belagavi in March 2019. Dr. K. Murugesh Babu was the research guide for them.

- Dr. K. Murugesh Babu was awarded as Best Guide from Karnataka State Council for Science and Technology, Bangalore, India in 2017 for guiding students’ project(Project Title: Design & Development of Natural Fibre Extracting Machine)

- Dr. K. Murugesh Babu was Recognized as ‘Technical Referee’ for the following International Journals: Textile Research Journal (USA), Journal of Applied Polymer Science (USA), Research Journal of Textiles and Apparel (Hong Kong), (Acted as a Special Editor for May 2008 issue of this journal), Smart Materials and Structures (USA), Journal of Industrial Ecology, Journal of Industrial Textiles, Journal of Natural Fibres.

- Dr. K. Murugesh Babu was recognised as ‘Expert Reviewer’ for “Biotechnology Ignition Grant (BIG) KIIT- Technology Business Incubator– Bhubaneswar, India in 2016

- Dr. K. Murugesh Babu was selected as Subject Expert/Advisor’ Union Public Service Commission, New Delhi

- Dr. K. Murugesh Babu was nominated as “Member of Scientific Partners” for the Master’s Programme in Textiles of University of Douala, Douala, Cameroon and Central Africa.

- Biography of Dr. Murugesh Babu published in Marquis Who's Who 2010, 27th Edition

- Dr. K. Murugesh Babu authored a text book titled Silk- Processing, properties and applications and published in Elsevier (USA) in 2016 and second edition of the same book was released in 2019

- Mr. Nandeesh R S attended 2 days training program on “Quality Certification of products” organized by Bureau of Indian Standards (mentors club) in Margao, Goa, on 13th and 14th Feb 2024

- Dr. K B Ravindra, Dr. Dinesh Y N and Dr. S M Chandrasekhara, published a paper in Asian Dyer, June-July 2022, titled “Antimicrobial activity of fabrics with natural dyes”.

- S N Ramesh, Associate Professor was awarded Ph. D. degree from VTU, Belagavi in March 2019. Dr. J S Muralidhara, was his research guide.

- Mrs. Kavya L, hss reported for the duty as Assistant Professor, in Department of Textile Technology on 9-9-24.

- Mr. Nandeesh attended one day seminar on “Research project proposal submissions” at Biotech seminar hall on 21-10-24.

- Under Dr. S M Chadrasekhra, Associate Professor, four research scholores have registered for Ph.D in Textile Technology at DEpt. of Textile Technology research centre, BIET, under VTU Belagavi.

- Dr. Y. N. Dinesh appointed as External member for evaluation of Ph. D scholars of research center in Textile board, Shivaji university, Maharastra

- Dr. Dinesh Y N, Professor and Head, appointed as chairman and Dr. Chadrasekhara, Associate Professor as member of BOS of VTU, Textile/Silk Board for the year 2022-2023.

- Dr. Y. N. Dinesh, and Dr. Chandrasekhara S M are recognized as research supervisors, Department of Textile Technology and research Centre, BIET by VTU, Belgaum and four research scholars have registered for Ph. D under them.

- Under Dr. Y N Dinesh, Professor and Head, four research scholores have registered for Ph.D in Textile Technology at DEpt. of Textile Technology research centre, BIET, under VTU Belagavi.

- Dr. Y N Dinesh successfully completed the NPTEL Online certification course on “Effective Engineering Teaching in Practice” with a consolidated score of 92% in Jan-Feb 2024

- Mr. Shashank attended training program on “VTU Consortium e-resources for library professionals for faculty and research scholars” held at UBDT, Davangere on 23-10-24

- Dr. Dinesh Y N, Dr. S M Chandrasekhara and Dr. K B Ravindra faculty members attended two day workshop on “Effetcive English Communication, Content and Language Integrated Learning (CLIL) on 12-13 Sept. 2024 held at Placement cell, BIET.

Student Achievements

- Final year project titled “Study of yarn and fabric properties produced from recycled cotton fibres” guided by Dr. S N Ramesh was sanctioned by KSCST for the year 2019-20.

- Final year project titled “Development of sanitary products using bamboo and organic cotton fibres” guided by Dr. S N Chandrasekhara was sanctioned by KSCST, for the year 2019-20.

- A paper titled “Air flow dyeing- An ecofriendly dyeing technology” authored by Manasa A of VII sem was published in On line J. of textile school, April 2019.

- A paper titled “Production of regenerated and sustainable fibres from Bio resources” authored by Hitesh D of V sem was published in Asian Tex. J., Sep.2019.

- A paper titled “Ecofriendly specialty fibres from bio resources” authored by Hitesh D of V sem was published in World J. of Tex. Eng. Tech., 2019

- Students participated in various seminars and symposiums and presented papers (about 15 during the year 2018-19) on current and specified topics. They also won prizes.

- VTU Ranks Year 2017-18 - Pavitra, I Rank, Anusha Crispin IV Rank, Ranganath, V Rank, Karthik Kumar VI Rank

- Final year project titled “Design and development of modified natural fibre extraction machine for opening of textile waste” was selected for KSCST seminar/exhibition 2017-18 as future development project. The project was guided by Dr. K. Murugesh Babu

- VTU Ranks Year 2016-17

- Soujanya P, I Rank,

- Ganesh G, II Rank,

- Keerthana Jambagi III Rank

- Kuldeep N, VII Rank.

- “Innovative methods of dyeing Tussar silk yarn fabric for the rural upliftment” guided by Dr. Dinesh Y.N and carried out by Sarvesh Kasat, Madan N S, Varun I Haligol and Charanth Hosmat.

- Twenty final year students got selected by various Textile/Garment industries in the campus interview held at the Institute placement cell and four students pursued their higher studies. The department achieved 76% placement.

Sl.NO Company On-campus/off-campus No of Student

1. Shahi Exports Pvt. Ltd. Bangalore On-campus 03

2. Gokaldas Exports Ltd. Bangalore off-campus 03

3. Avery Dennison India Pvt, Ltd off-campus 02

4. Aravind mills Bangalore off-campus 05

5. Vishwaa Apparels off-campus 02

6. Laguna Clothing Pvt. Ltd. off-campus 02

7. Wonder blues Apparels Pvt. Ltd off-campus 01

8. Positex Pvt. Ltd, Bangalore off-campus 01

9. Intratech Pvt. Ltd, Bangalore off-campus 01

- The final year project work Titled " Modification of Amber Charaka – a Khadi spinning machine" carried out under the guidance of Dr. K B Ravindra is awarded as "Innovative project of the year -2024". The project was sponsored by Institute and got the sanction of Rs. 5000.00.

- All the VIII semester students completed Internship in various Garment & Retail Sectors in and around

Bangalore. Almost 80% of the students are offered for Job in the respective campiness where Internship was carried out

- Two final year projects selected for exhibition in Nirmana-5 an in-house final year project exhibition. Among them the project titled "Development of flame retardant and wrinkle resistant cellulosic fabric using Eco-friendly finishing agents” awarded as best project. The project was carried out by Deepak Dewasi, Srujan. N. H, Smitha GM, Sritej R Kandakur and guided by Dr. Y N Dinesh

- Ms. Shruthi Shenai, secured VTU first rank for the year 2022-23.

- The final year student project titled “Modification of Amber Charaka – A Khadi Spinning Machine” was sponsored by Institute and sanctioned Rs, 5000.00. The project also awarded as best project in the in -house project Exhibition NIRMANA-2024 organized by the Institute for the year 2023-24.

- The department received 02 Ranks from VTU, for the year 2023-24.

- Final year project titled “Study of yarn and fabric properties produced from recycled cotton fibres” guided by Dr. S N Ramesh was sanctioned by KSCST for the year 2019-20.

- Final year project titled “Development of sanitary products using bamboo and organic cotton fibres” guided by Dr. S N Chandrasekhara was sanctioned by KSCST, for the year 2019-20.

- A paper titled “Air flow dyeing- An ecofriendly dyeing technology” authored by Manasa A of VII sem was published in On line J. of textile school, April 2019.

- A paper titled “Production of regenerated and sustainable fibres from Bio resources” authored by Hitesh D of V sem was published in Asian Tex. J., Sep.2019.

- A paper titled “Ecofriendly specialty fibres from bio resources” authored by Hitesh D of V sem was published in World J. of Tex. Eng. Tech., 2019

- Students participated in various seminars and symposiums and presented papers (about 15 during the year 2018-19) on current and specified topics. They also won prizes.

- VTU Ranks Year 2017-18 - Pavitra, I Rank, Anusha Crispin IV Rank, Ranganath, V Rank, Karthik Kumar VI Rank

- Final year project titled “Design and development of modified natural fibre extraction machine for opening of textile waste” was selected for KSCST seminar/exhibition 2017-18 as future development project. The project was guided by Dr. K. Murugesh Babu

- VTU Ranks Year 2016-17 - Soujanya P, I Rank, - Ganesh G, II Rank, - Keerthana Jambagi III Rank - Kuldeep N, VII Rank.

- “Innovative methods of dyeing Tussar silk yarn fabric for the rural upliftment” guided by Dr. Dinesh Y.N and carried out by Sarvesh Kasat, Madan N S, Varun I Haligol and Charanth Hosmat.

- Twenty final year students got selected by various Textile/Garment industries in the campus interview held at the Institute placement cell and four students pursued their higher studies. The department achieved 76% placement. Sl.NO Company On-campus/off-campus No of Student 1. Shahi Exports Pvt. Ltd. Bangalore On-campus 03 2. Gokaldas Exports Ltd. Bangalore off-campus 03 3. Avery Dennison India Pvt, Ltd off-campus 02 4. Aravind mills Bangalore off-campus 05 5. Vishwaa Apparels off-campus 02 6. Laguna Clothing Pvt. Ltd. off-campus 02 7. Wonder blues Apparels Pvt. Ltd off-campus 01 8. Positex Pvt. Ltd, Bangalore off-campus 01 9. Intratech Pvt. Ltd, Bangalore off-campus 01

- The final year project work Titled " Modification of Amber Charaka – a Khadi spinning machine" carried out under the guidance of Dr. K B Ravindra is awarded as "Innovative project of the year -2024". The project was sponsored by Institute and got the sanction of Rs. 5000.00.

- All the VIII semester students completed Internship in various Garment & Retail Sectors in and around Bangalore. Almost 80% of the students are offered for Job in the respective campiness where Internship was carried out

- Two final year projects selected for exhibition in Nirmana-5 an in-house final year project exhibition. Among them the project titled "Development of flame retardant and wrinkle resistant cellulosic fabric using Eco-friendly finishing agents” awarded as best project. The project was carried out by Deepak Dewasi, Srujan. N. H, Smitha GM, Sritej R Kandakur and guided by Dr. Y N Dinesh

- Ms. Shruthi Shenai, secured VTU first rank for the year 2022-23.

- The final year student project titled “Modification of Amber Charaka – A Khadi Spinning Machine” was sponsored by Institute and sanctioned Rs, 5000.00. The project also awarded as best project in the in -house project Exhibition NIRMANA-2024 organized by the Institute for the year 2023-24.

- The department received 02 Ranks from VTU, for the year 2023-24.

Forum Activities

Textile FORUM (TXFORUM)

Textile Forum includes all textile students as members, a student convener and a staff convener are to take responsibility of the forum activities. Departmental activities are conducted under textile forum. Dr. S M Chandrasekhara, Asst. Professor is the convener and monitor the activities of forum.

The following events are conducted regularly by TXForum:

| Sl.No. | Event | Event Descrption |

|---|---|---|

| 3. | Publications | A paper titled “Antimicrobial Finishes in the Textile Industry” authored by Dr. Y N Dinesh and Ms. Mamatha G P K, Research scholar in Asian Textiles Journal, Oct.-Nov. 2024. |

| 4. | TEXCREATIVE-24 | Department organised a one day technical symposium for students “TEXCREATIVE-24” on 15-3-2024. Textile Technology students from various Institutes, across the country participated in the event and presented their papers. Students of the department presented 3 papers and participated in TEXQUIZ and TEX-TYGOON events. Mr. Sritej and Mr. Deepak Dewasi of 6th semester got 1st prize and Pooja D M and Pavan of 8th semester got 3rd prize in paper presentation competitions. |

| 5. | Welcome for 3rd sem students | Inauguration of Textile forum activities for the year 2024-25 was arranged on 9-10-24 in Garment lab. Ms. Dhanalakshmi (an Alumnus) PPC and Marketing, Shahi Exports P Ltd,. Shimoga was the chief guest and she spoke about the responsibilities of students in shaping their future career. |

| 5. | Project exhibition NIRMANA-04-2024 | 1. The final year student project titled “Modification of Amber Charaka – A Khadi Spinning Machine” was sponsored by the Research and Innovation centre, BIET and sanctioned Rs. 5000.00. The project also awarded as best project in the in -house project Exhibition NIRMANA-4.0 organised by the Institute in campus premises on 6-9-24. |

| 8. | Technical talk | A technical talk was conducted for department students on 21st and 22nd June 24. Dr. J Hayavadana, HOD, Dept. of Textile Technology, Osmania University, Hyderabad was the resource person. Spoke on Textile Structure and Design. |

| 11. | Alumni meet | An alumni meet was conducted for 2024 output batch on 28-9-24 Saturday in Garment laboratory. Er. Vijayendra Babu, Senior Vice President –Operations, Grasim Industries, Kumarapatnam, Harihara was the Chief Guest and distributed the Degree Certificates to the 2024 output batch students. On the occasion he also spoke on "Career growth and employment opportunities in Fibers manufacturing industry". |

| 12. | Work shop | Department conducted workshop for 3rd semester students on Skill development from 22 to25 Jan 2024. |

| 13. | YOGA class | Department of Textile Technology organised YOGA class on International Yoga Day on 21/06/2022. |

| 13. | TEXCREATIVE-2024 | 6. Department organised a one day technical symposium for students “TEXCREATIVE-24” on 15-3-2024. Textile Technology students from various Institutes, across the country participated in the event and presented their papers.Students of the department presented 3 papers and participated in TEXQUIZ and TEX-TYGOON events. Mr. Sritej and Mr. Deepak Dewasi of 6th semester got 1st prize and Pooja D M and Pavan of 8th semester got 3rd prize in paper presentation competitions. |

Department Activities

The following department activities were conducted:

- Third semester students of the department visited Sree Anjaneya cotton mills, Davangere on 29-01-24. Students observed working of cotton spinning systems and updated their practical knowledge.

- A review paper titled “Antimicrobial properties of some natural dye – A review”, authored by K B Ravindra, Y N Dinesh and S M Chandrasekhara is published in Trends in Textile Engineering & Fashion Technology, 10(3).2024

- 1. Dr. Dinesh Y N, Dr. S M Chandrasekhara and Dr. K B Ravindra faculty members attended two day workshop on “Effective English Communication, Content and Language Integrated Learning (CLIL) on 12-13 Sept. 2024 held at Placement cell, BIET. 2. Dr. S M Chandrasekhara and Dr. K B Ravindra faculty members successfully completed certificate course titled “Energy Literacy Training” on 6-9-24. 3. Mr. Nandeesh attended one day seminar on “Research project proposal submissions” at Biotech seminar hall on 21-10-24. 4. Mr. Shashank attended training program on “VTU Consortium e-resources for library professionals for faculty and research scholars” held at UBDT, Davangere on 23-10-24

- Mrs. Kavya L, has reported for the duty as Assistant Professor, in Department of Textile Technology on 9-9-24.

- A paper titled “Metamorphosis of Textile Waste – Understanding Closed Loop Management in the Textile Industry” authored by Mamatha G P K, Ph. D scholar, and Dr. Y N Dinesh, HOD in 14th International Conference on Sustainable Waste Management – Circular Economy and IPLA Global Forum 2024 held at GITAM school of business, GITAM (deemed to be University), Visakhapatnam, India on November 29th to December 1st 2024.

- A research paper titled “Investigation of antimicrobial activity of cotton and blended fabrics treated with natural bioactive agents” authored by K B Ravindra, Y N Dinesh and S M Chandrasekhara was published in International Journal in IT & Engineering (IJITE) Volume 12 Issue 05, May 2024

- A research paper titled “Applications of Biomimetics in Textiles - A review” authored by Y N Dinesh and S M Chandrasekhara is published in International Journal of Engineering & Scientific Research, Vol.12, Issue 05, May 2024,

- Self-Employment schemes. National level Awareness programme (KVIC & Khadi Gramodyoga) on 25-02-2020. About 80 students including some and local entrepreneurs participated in the program

- Industrial visit was organised for 5th semester students on 22 – 24 Feb 2024. Students are accompanied with Mr. Nandeesh R S and visited Krishan Texchem Pvt. Ltd, a suiting manufacturing unit, Thandya Industrial area, Pandavapura, Nanjanagudu, Mysore.

- A workshop was organized for department students on 21st and 22nd June 24. Dr. J Hayavadana, HOD, Dept. of Textile Technology, Osmania University, Hyderabad was the resource person and spoke on “Weaving Technology, Textile Structure and Design”.

- Following student projects are approved by New Age Innovation Network (NAIN), a program by the Govt. of Karnataka, sanctioned Rs. 3 Lakh each. SL No Title Guide Name Amount sanctioned Rs. 1 Modification of hand operated Khadi yarn spinning machine for improved yarn quality and production Dr S M Chandrasakara 3 Lakh 2 Development of Bio-composites from areca husk fibres for sound and thermal insulation application Nandeesh R S 3 Lakh

- The Department has organised a workshop on “Preparation of scheme and syllabus of B. Tech (Textile Technology)” on 12-04-2025. All the BOS members including Dr. R Indushekar, Director, DRDO and Dr. Lavate, Asso Proffessor, Dr. Naveen Padki, Senior scientist, Central Silk Board were present.

- In association with NAIN, the department organised a one day workshop on 12-13, March 2025 on “Consumer behaviour-driving sustainable apparel innovation and entrepreneurship”. Dr. Selvadas HOD, Department of Fashion, Garden city University, Bangalore and Ms. Mamatha G P K were the resource persons.